Larger allowable moment of inertia, stronger performance, suitable for multi-piece handling by large end actuators

Battery-free motor unit

No need to replace batteries

Reduced downtime

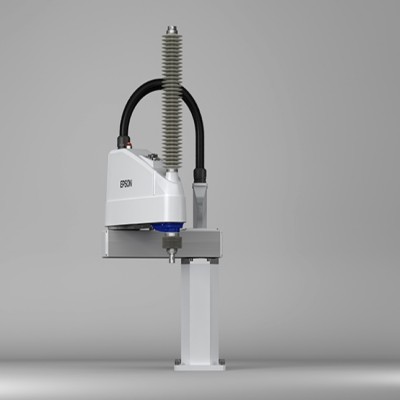

J2 the top of the joint add Ethernet connection port, built-in Cat 5e camera cable, easy to move camera installation

The second arm is inclined out of line, more compact in shape and less space for installation

General I/O interface, more applicable controller

Like RC700-A controllers, RC90-B controllers support NPN /PNP two wiring modes.

M/C cable with simple detachable structure

• Disassembly without using tools for easy unloading

• Easy to install and replace robots inside equipment

Product name | LS20-B | ||

Product model | LS20-B804* | LS20-BA04* | |

Installation method | Table installation | ||

Arm length | 1-2 axis arm | 800 mm | 1000 mm |

Maximum movement speed | J1-2 | 9940 mm/s | 11250 mm/s |

J3 | 2300 mm/s | ||

J4 | 1400°/s | ||

Body weight (excluding cable) | 48 kg | 51 kg | |

Repeat positioning accuracy | J1-2 | ±0.025 mm | |

J3 | ±0.01 mm | ||

J4 | ±0.01° | ||

Maximum range of motion | J1 | ±132° | |

J2 | ±152° | ||

J3 | 420 mm | ||

J4 | ±360° | ||

Load * 1 | Rating | 10 kg | |

Maximum | 20 kg | ||

Standard cycle time * 2 | 39 sec | 0.43sec | |

Allowable moment of inertia of the fourth joint * 3 | Rating | 0.05 kg·㎡ | |

Maximum | 1.00 kg·㎡ | ||

Motor power consumption | J1 | 750 W | |

J2 | 520 W | ||

J3 | 520 W | ||

J4 | 150 W | ||

Apical pressure of the third joint | 250 N | ||

Origin Return | No need to reset the origin | ||

User circuit | 15 pin (D-sub interface), RJ45 8 pin (cat 5e) | ||

User gas path | ø6mm×2, ø8mm×2 Withstand voltage:0.59 MPa(6 kgf/cm2 )(86 psi) | ||

Installation environment | Standard / clean * 4 | ||

Applicable controller

| RC90-B | ||

safety standards | CE,KC,ANSI/RIA R15.06-2012,NFPA 79 (2007 Edication) | ||