The manufacturing landscape is shifting decisively from mass production to high-mix, low-volume orders. Industries like home appliances and metal fabrication now face highly dynamic and fragmented demand—surges for specific appliance models during sales events, seasonal peaks for hardware during construction periods, and even "one drawing per customer" customization have become commonplace.

Customer expectations for fast delivery, however, remain stringent regardless of order fluctuations. The ability to respond rapidly to changing orders while maintaining high productivity has become a crucial competitive advantage. This new reality demands unprecedented levels of flexibility, intelligence, and responsiveness from bending production lines, exposing multiple challenges in traditional bending methods:

Efficiency Bottlenecks: Manual operations limit production cycle times, leading to slow response for batch orders.

Inconsistent Quality: Bending accuracy and springback compensation rely heavily on operator skill, resulting in unpredictable quality and yield.

High Labor Costs: Physically demanding work increases labor costs and makes talent retention difficult.

Changeover Downtime: Switching products requires lengthy, experience-dependent die and machine adjustments, crippling adaptability for small-batch, high-variety production.

Line Reconfiguration: From Rigid Lines to Flexible "Transformers"

To overcome these challenges, modern bending lines must be fundamentally reconfigured. The core of this transformation lies in modular hardware and rapid-changeover systems that drastically reduce time for die and gripper switching, creating production lines that function like flexible "Transformers."

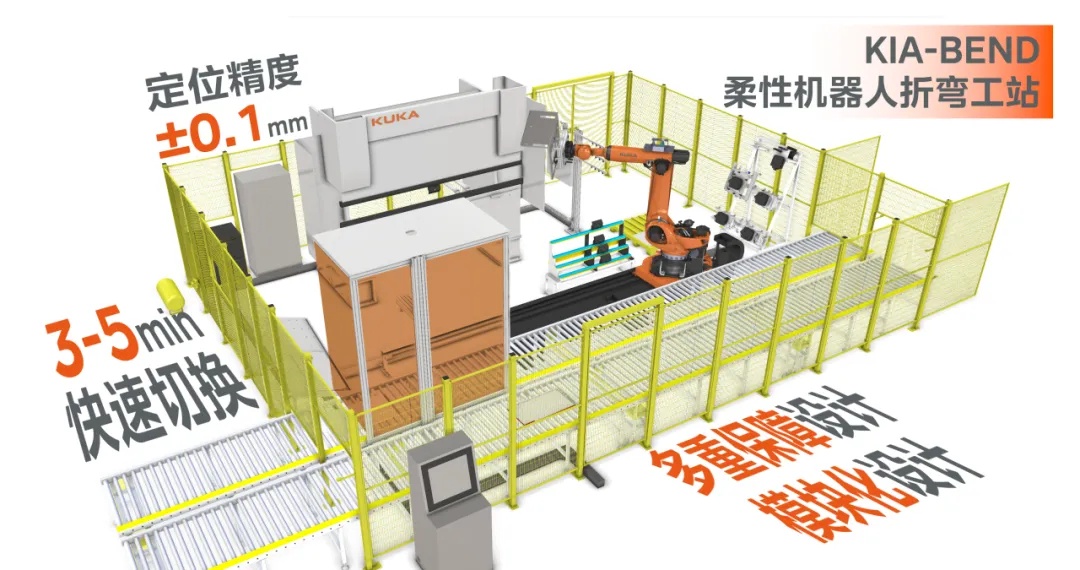

KUKA Industrial Automation's KIA-BEND Flexible Robotic Bending Cell exemplifies this vision. This integrated workstation combines robots, vision systems, and intelligent control to automate the entire process—from inspection and picking to bending and stacking—delivering a highly efficient and precise unmanned bending line.

Key Advantages of the KIA-BEND Flexible Cell

Rapid Changeover for Maximum Efficiency

Featuring a modular design, the cell's press brake is equipped with hydraulic clamping and quick-change systems, enabling extremely fast program, die, and gripper swaps. Combined with a gravity positioning table and turnover rack, it handles sheet metal parts (1-3mm thickness) of various sizes, achieving changeover times of just 3-5 minutes between different products—ideal for high-mix, low-volume production.Precision Control for Guaranteed Quality

KUKA's specialized bending software package enables integrated control between the robot and the press brake, featuring automatic trajectory optimization for consistent, high-precision bends.Intelligent Vision for Automated Recognition

An integrated 2D vision system automatically detects the position, type, and orientation (front/back) of incoming sheet metal, achieving a positioning accuracy of ±0.1mm and eliminating human error at the source.Comprehensive Safety Protection

A multi-layer safety system, including safety light curtains, door interlock switches, and a safety controller, ensures a protected operating environment.Reduced Labor & Stable Output

Utilizing the KR210 R2700-2 industrial robot, the cell ensures stable 24/7 operation and can effortlessly handle different sheet metal sizes. This significantly boosts equipment utilization and output efficiency while reducing physical strain and reliance on manual labor.

Proven Results: Flexible Bending Cells in Action

Case Study: Foshan Automation Line

After implementing the KIA-BEND cell, this line achieved a record-breaking cycle time of 10 seconds per bend (for a 400x400x1.2mm part, no flipping). It gained the capability to process 14-25 different sheet metal parts, increased overall capacity by 50%, and saved 2 operators per shift.Case Study: Suzhou Precision Technology Co., Ltd.

This workstation is used for automatically bending sheet metal for cloud server enclosures. It achieves an average cycle time of 50 seconds per bend (for a 1900x1800x3mm part, with flipping) and successfully handles 22 different types of 3mm thick sheet metal components, automating the entire process from destacking and positioning to bending, flipping, and palletizing.

Conclusion

As a global leader in industrial automation, KUKA is driving the intelligent transformation of the sheet metal processing industry through innovative, flexible manufacturing solutions like KIA-BEND. In the realm of discrete manufacturing, there is no universal formula—only tailored, smart solutions that address specific production pain points can empower businesses to break through bottlenecks and build a decisive competitive edge in a volatile market.