The electrical equipment industry, characterized by high-mix, low-volume production, faces chronic inefficiencies. Traditional line changeovers can halt operations for 2-3 days, while manual inspections and information silos further cripple productivity.

As a key supplier to giants like Siemens and Schneider, Nanjing Xie'ao Intelligent Control Co., Ltd. was no stranger to these challenges of discrete manufacturing and volatile order demands.

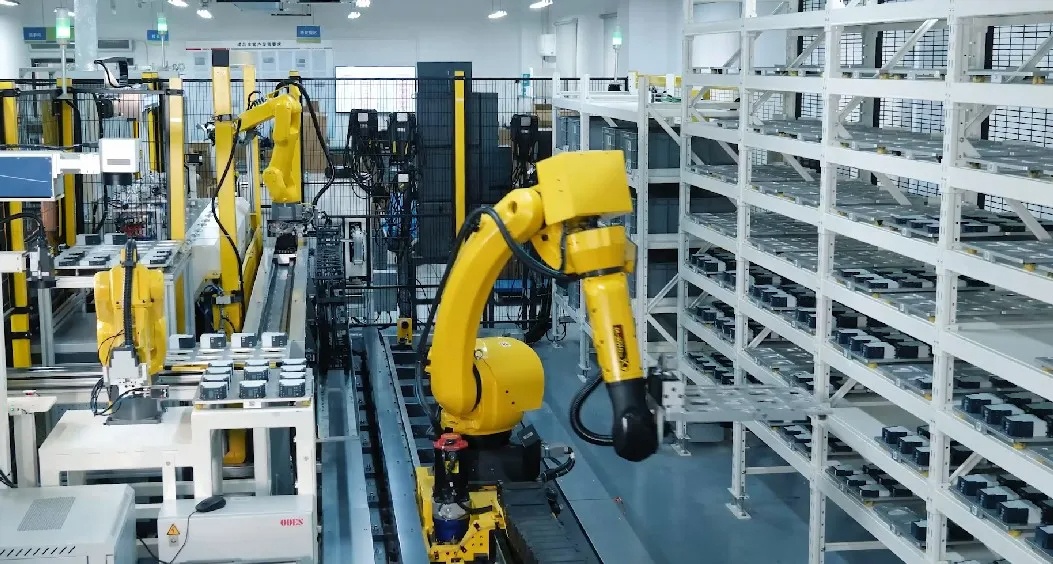

To break this cycle, Xie'ao partnered with Shanghai FANUC for a comprehensive line overhaul. The solution integrated marking, inspection, packaging, and automated storage with a dedicated "Electrical MES" digital platform. This suite enabled precise material tracking, dynamic delivery control, and optimized labor allocation.

The result was a dramatic compression of the production cycle. Xie'ao can now deliver any product within 7 days, a feat that secures a critical competitive edge. This case demonstrates that in discrete manufacturing, tailored smart solutions, not one-size-fits-all formulas, are the key to unlocking efficiency.