How to Achieve Ultimate Efficiency, Flexible Production, and Stable Transfer in Stamping Automation? ABB's Solution: The Game-Changing New IRB 7710 SFX High-Speed Stamping Robot.

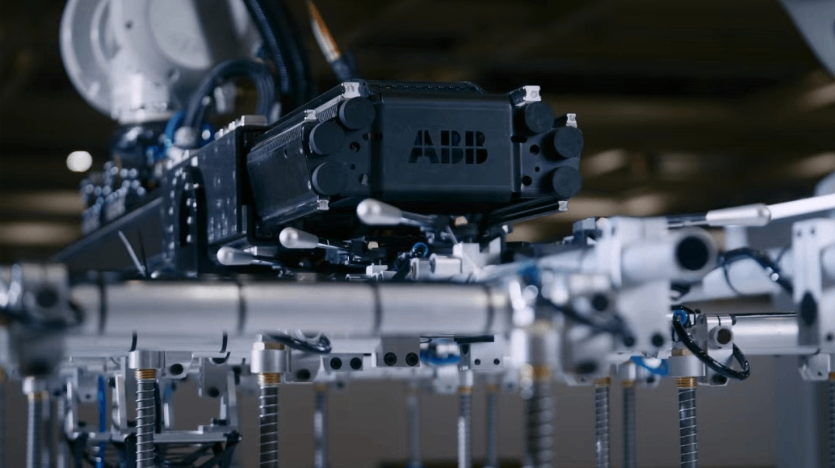

ABB provides the answer with its groundbreaking solution – the new IRB 7710 SFX high-speed stamping robot. It not only boosts production capacity with leading speed but also offers powerful flexibility to adapt to diverse stamping scenarios. The lightweight design of its carbon fiber 7-axis structure ensures ultra-stable performance during part transfer, laying a solid foundation for precision stamping.

Four Core Advantages Driving Technological Innovation

Ultimate Productivity: ABB pioneered and introduces the third-generation high-speed robot solution specifically designed for stamping, achieving a record 15 strokes per minute – the fastest speed ever in ABB's history!

Exceptional Flexibility: Beyond the standard 7-axis configuration (robot + linear axis), it can be equipped with both tilting and separation function modules. This efficient modular design allows for expansion up to a maximum of 11 axes, meeting the comprehensive needs of modern stamping shops for multi-tasking and high adaptability.

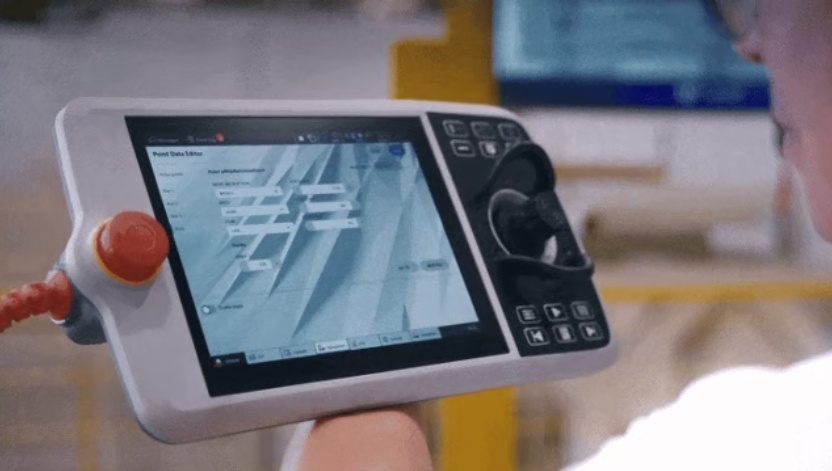

Energy Saving & Environmental Protection: Equipped with the OmniCore controller and its regenerative power technology, it can feed energy back into the grid, achieving energy savings of up to 30% and promoting green manufacturing.

Ease of Use: ABB's newly upgraded StampWare dedicated stamping software package delivers superior operation and user experience, significantly reducing the learning curve and operational barriers, thereby enhancing production efficiency.

Intelligent Dynamic Model: Balancing Speed and Longevity

Leveraging the powerful performance of the OmniCore controller and the integrated dynamic model, the IRB 7710 SFX ensures all axes always operate at their optimal speed. This not only improves motion precision but also effectively reduces mechanical wear, thereby significantly extending the equipment's service life.

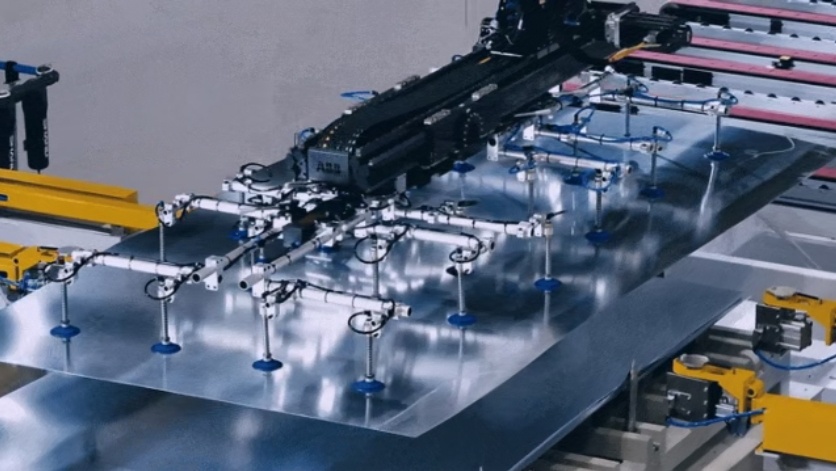

Part Transfer Optimization: Further Reducing Cycle Time

The robot achieves a linear, optimized path from loading to unloading, enabling parallel transfer between presses. This method reduces vibration, allows for smaller press spacing, and effectively shortens the cycle time. The optional separation and tilting units grant additional flexibility and can further help increase the production cycle.

Modular Design: Flexible Configurations to Suit Your Needs

The IRB 7710 SFX offers various configuration combinations to adapt to different production line requirements:

6+1-axis: IRB 7710 + LinAx

6+3-axis: IRB 7710 + LinAx + 2x Tilting Units | IRB 7710 + LinAx + 2x Separation Units

6+5-axis: IRB 7710 + LinAx + 2x Tilting Units + 2x Separation Units