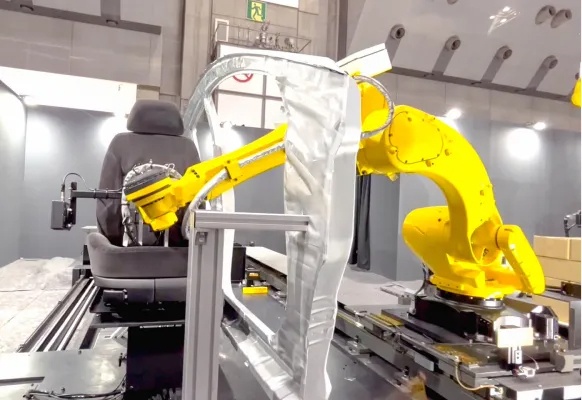

The highly popular six-axis M-710 series has received a comprehensive upgrade! FANUC proudly introduces the new M-710iD/50M and M-710iD/70 robots, establishing new benchmarks for machine tending, material handling, assembly, palletizing, and welding applications.

Building upon the proven legacy of the M-710iC series in precision, efficiency, versatility, and ease of use, the new M-710iD models incorporate several key enhancements to deliver exceptional performance across diverse scenarios.

The M-710iD/50M offers a substantial 2606mm reach with a repeat positioning accuracy of ±0.06mm. Compared to its predecessor, the M-710iC/45M, its maximum payload has been increased by 5kg to 50kg. An innovative curved J2-axis design minimizes interference with workpieces or fixtures when the arm reaches deep into containers, ensuring smoother and safer movement.

The entire new M-710iD series features a fully enclosed structure, achieving IP67-rated protection against dust and water jets. This allows for reliable operation even in demanding environments like machine tending, deburring, and die-casting part extraction. The service-friendly arm design also fully integrates I/O signal and air supply connections.

Simultaneously launched, the M-710iD/70 combines the high-speed characteristics of the 50kg model with a robust 70kg payload capacity. It provides a reach of 2104mm and an impressive repeat positioning accuracy of ±0.03mm.

A notable feature is the series' inherent flexibility. The entire M-710iD lineup can be configured for use as a five-axis palletizing robot by simply selecting the palletizing option mode, requiring no additional hardware. Furthermore, the new series supports multiple mounting options—floor, wall, and inverted—significantly enhancing application flexibility.

The new M-710iD series is ideally suited for a wide range of industries including automotive, electronics, pharmaceuticals, food/medical, machining, foundry, and injection molding, effortlessly tackling various production conditions and injecting new driving force into modern manufacturing.