about SPIRAXSCARO

Steam can heat or sterilise almost any industrial process. That’s why it’s often the first choice in so many applications around the world. From food producing to oil refining, beer making, and drug manufacturing companies, Steam is well known for delivering safe, sustainable and efficient energy.

As many companies continue to face energy challenges, high operational costs and tight legislation, Spirax Sarco can help you to:

Cut emissions, energy waste and water use;

Boost productivity and reliability;

Drive operational reliability;

Lower costs.

We don’t just sell steam products; we’ll power your process improvements.

Our team is passionate about steam. Your local engineers will use their industry know-how to find and fix problems in your steam process. The best part is that our hardworking team of 1,300 steam experts are right on your doorstep, across 62 countries.

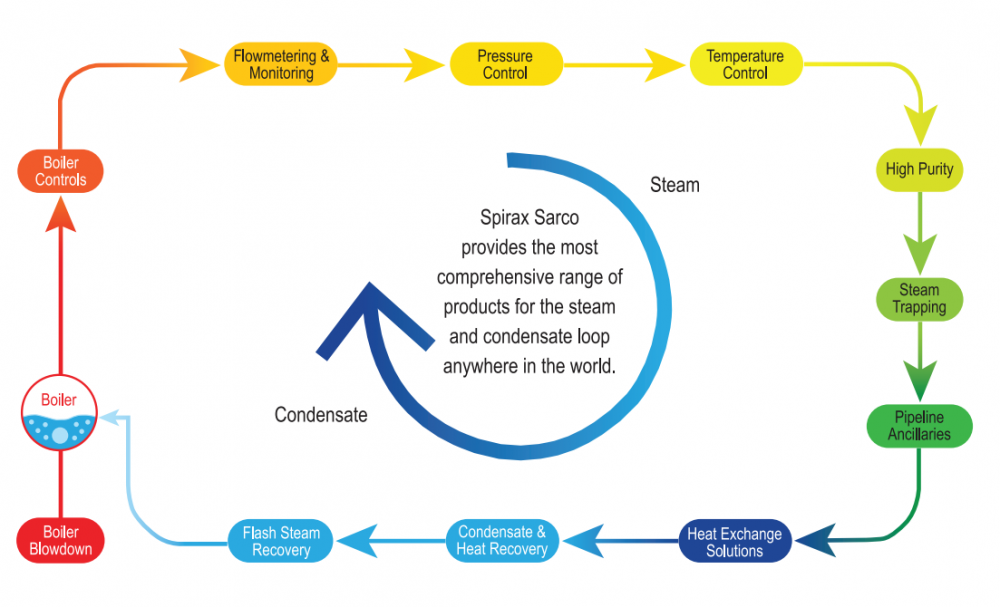

SPIRAXSCARO PRODUCTS

Boiler controls and systems

Condenate and heat recovery systems

Control systems

Flowmetring

Heat transfer solutions

Steam traps

Compressed air

Pipeline ancillaries

Isolation valves

Clean steam

Printed product literture request

PTODUCET DESRIPTION

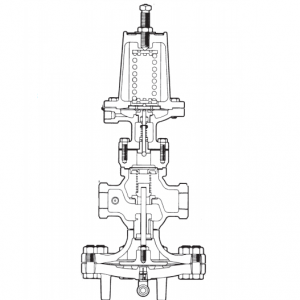

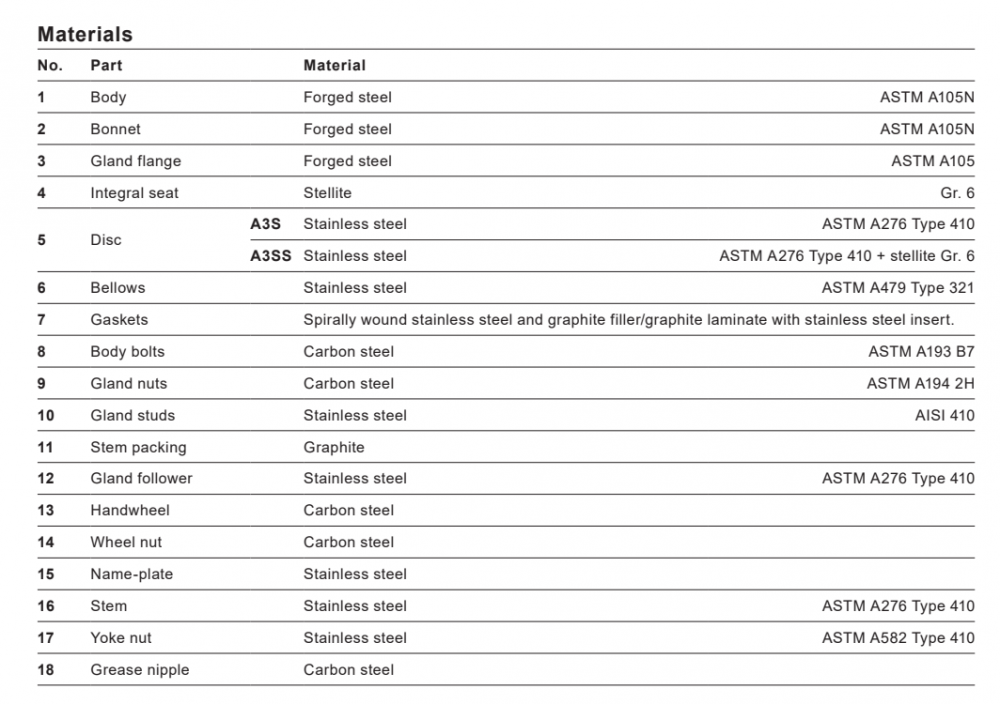

Spirax Sarco bellows sealed isolation valves are engineered to maintain plant safety and save energy by totally eliminating stem seal leaks. Zero emissions are guaranteed which ensures our BSA valves meet the most stringent worldwide emissions legislation. The BSA_T offers a throttling plug as opposed to the standard flat disc. The throttling plug allows manual regulation to adjust line pressure and flow, making this a flexible and user-friendly isolation solution. It can also be used as a basic control valve or a substitute for ‘bypass’ lines. The throttling plug version also benefits from having twin ply bellows which will extend the products service life. Those valves fitted with a throttling plug have a locking screw as standard, enabling the user to lock the valve in the throttling position.

Key features and benefits:

• Bellows sealed design eliminates emissions for improved energy efficiency.

• Fully compliant with the European Pressure Equipment Directive 97/23/ EC.

• Maintenance free giving long life and low cost of ownership.

• Unaffected by vibration and will operate over a wide range of pressures and temperatures.

PRODUCT SPECIFICATION

The high integrity A3S bellows sealed valve is suitable for use under higher pressure steam, gas, and liquid applications as it is designed to ASME Class 800.

Isolation valves are essential whether you need to divert flow or shut down your system for safe maintenance of your equipment.

| Sizes and pipe connection | ||

| ½", ¾", 1", 1¼", 1½" and 2" | ||

| Screwed BSP (BS 21 parallel), NPT | ||

| Socket weld to BS 3799 /ANSI B 16.11 | ||

| Pressure / temperature limits (Class 800) | ||

| Body design conditions | Class 800 | |

| PMA | Maximum allowable pressure | 136 bar g |

| TMA | Maximum allowable temperature | 425°C |

| Minimum allowable temperature | -29°C | |

| PMO | Maximum operating pressure | 99 bar g @ 360°C |

| Maximum operating pressure for extended bellows life | 40 bar g @ 400°C | |

| TMO | Maximum operating temperature | 425°C |

| Maximum operating temperature for extended bellows life | 400°C @ 40 bar g | |

| Minimum operating temperature | -29°C | |

| Without the bellows fitted the unit is designed for a maximum cold hydraulic test pressure of: | 212 bar g | |

STANDARDS

This product fully complies with the requirements of the Pressure Equipment Directive (PED).

The valve bellows fatigue life conforms to ISO 15761.