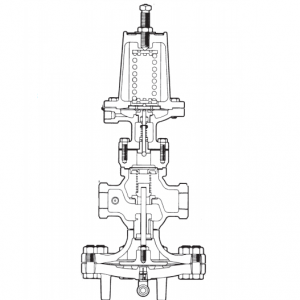

Airodyn Spyshakcompressed air trap has a disc that is both sensitive and action actuator. When the device starts, there is cooling condensate water in the pipeline. The condensate water pushes away the valve disc by working pressure and is quickly discharged. When condensate discharge is complete, steam enters the trap, and the volume of steam expands rapidly. Steam is larger than the flow rate of condensate, resulting in pressure difference between the upper and lower parts of the valve disc, and the valve disc quickly closes under the suction force of the steam flow rate. When the valve plate is closed, the valve plate is under pressure on both sides, the force area below the valve plate is less than the force area above, because the pressure in the trap chamber comes from the steam pressure, so the force above the valve plate is greater than the following, the valve plate is tightly closed. When the steam in the trap chamber cools down to condensate, the pressure in the chamber disappears. The condensate water pushes the valve disc by working pressure, and the condensate water continues to discharge, working in circulation, and discharging intermittently.

Structural features:

Small size, light weight, not limited by the installation position;

All materials are stainless steel parts, durable, corrosion resistant;

In the outdoor not afraid of freezing, water percussion, heat resistance;

The undercooling degree is 8 ℃, the steam leakage rate is less than 3% of the actual displacement, and the maximum back pressure is 50%;

Simple structure, convenient installation and maintenance.

Selection and installation:

When choosing the trap, do not choose according to the diameter of the pipe, according to the condensate generated by the equipment or pipeline to determine the maximum continuous displacement of the trap for 2-3 times the actual condensate is suitable;

The maximum allowable back pressure of the valve shall not exceed 50% of the inlet pressure.;The valve is used in the rated pressure or pressure difference (0.05-2.5Mpa) range without adjustment;

The valve installation, can be horizontal or left and right tilt, also can be installed from the top down drainage;But it is best not to drain from the bottom to the top of the installation (this will increase drainage resistance, affect the displacement);

A stop valve should be installed before the trap for easy maintenance. Generally, bypass piping is not required. The valve is resistant to freezing and can be installed outdoors;

The valve must be installed at the low place of heating equipment and pipelines, where condensate accumulates. The condensate can be eliminated in time, not easy to accumulate in the equipment or pipeline;

Do not several equipment string, parallel with a trap, so easy to cause short circuit and uneven heating. Install separate traps;

The trap installation should consider the convenience of inspection and maintenance and replacement.

Operation guide:

Airodyn Spyshak compressed air trap operation period is generally 12 months, due to open the outlet body to remove dirt, cleaning screen, such as more media impurities, can be cleaned in advance as appropriate. The trap may be closed loosely because it has been used for too long. At this time, it is necessary to replace or maintain it in time (such as maintenance: open the outlet body, remove the valve cover and open it, check whether the valve disc and seat seal are worn. Can use 600 mesh gold and steel sand mixed oil on the platform grinding, to achieve the electric two pieces of mutual seal.