Spyshak SV615 safety valve introduction:

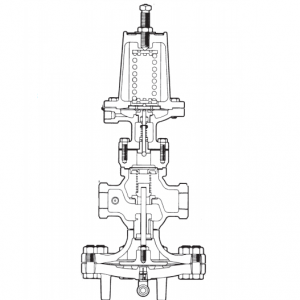

SV615 Full stroke, full nozzle relief valve, suitable for steam, air, non-chemical industrial gases and non-hazardous liquid applications.

The section describes the application of Spyshak SV615 safety valve:

SV615 safety valve: full stroke, full nozzle safety valve. Suitable for steam, air has no chemical effect of industrial gases and non-dangerous liquid applications. Used for steam or hot water boiler, generator, pressure vessel, air storage tank and air compressor, autoclave reducing valve downstream protection.

Caliber DN15~50, pressure PN25, threaded BSP or NPT connections, sanitary clamp connections are available for DN15~25. Sealing performance in accordance with API527 standards. Soft seal spool available. SV607/SV304 Safety valve: Full travel flange connection safety valve. Mainly used in steam boiler pipeline. Protection of pressure vessels, compressors and gas storage tanks and most industrial process equipment.

Meet the requirements of DIN320 TRD421, with TUV certification, caliber DN20~DN150, SV607 pressure level PN16/25, SV604 PN40/AN300, can be DIN and ANSI flange. Sealing performance in accordance with API527 standards. Soft seal spool can be provided according to customer's request.

SV615 British Spyshak safety valve advanced design, complete varieties, a wide range of materials (bronze, ductile iron, carbon steel, alloy steel, stainless steel and other materials), wide range of temperaturePan, all products have the authority of the certification. , can provide in line with different standards of safety valve requirements.

In the decompression station system, a safety valve must be installed downstream of the reducing valve to prevent the downstream pressure of the reducing valve from being higher than the rated pressure of the equipment. The set pressure of the safety valve must be within the maximum allowable pressure range of the equipment operation, and there must be enough pressure difference between the safety valve and the normal operating pressure to prevent frequent jumping of the safety valve from causing damage to the sealing surface. Safety valve setting must be carried out by qualified personnel. In the selection of safety valve, we should ensure that the maximum flow rate of the safety valve can flow through the reducing valve under the set pressure.

SV615 British Spacak Safety valve Parameters:

1. Required displacement of the system or equipment and the number of valves to be installed;

2. Opening pressure (or setting pressure);

3, the medium and its specific gravity (liquid medium) or molecular weight and compression coefficient (for gas medium);

4, valve inlet medium temperature;

5, whether there is back pressure, if so how much;

6, the requirements of the valve implementation standard (if there is no special indication, designated by the supplier).